Plastic Recycle Cutting Blade

2000-10000 INR/Piece

Product Details:

- Machine Type Plastic Recycling Machine

- Operate Method Mechanical

- Cutting Speed High

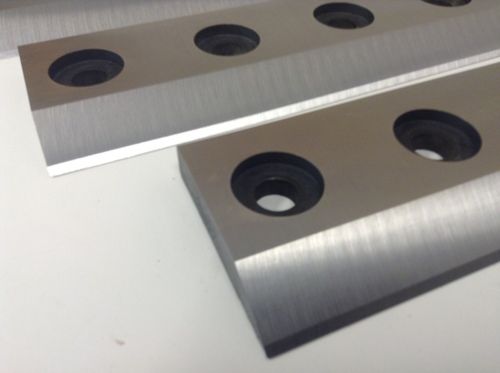

- Shape Rectangular with beveled edge

- Cutter Type Blade Cutter

- Cutting Capacity Supports thick and rigid plastics

- Features Corrosion-resistant, Wear-resistant, Long service life

- Click to View more

X

Plastic Recycle Cutting Blade Price And Quantity

- 2000-10000 INR/Piece

- 20 Piece

Plastic Recycle Cutting Blade Product Specifications

- Recycling/Cutting

- Mechanical

- High

- Plastic Recycling Machine

- Rectangular with beveled edge

- Blade Cutter

- Corrosion-resistant, Wear-resistant, Long service life

- 58-60 HRC

- Supports thick and rigid plastics

- N/A (Blade is flat/rectangular)

- Manual/Automatic

- Uncoated

- High-speed steel/Alloy steel

- 200 mm (customizable)

- Precision

- Heavy-duty

- Industrial Blade

Plastic Recycle Cutting Blade Trade Information

- 20 Piece Per Day

- 20 Days

Product Description

Backed by the rich industry understanding, we have been able to manufacture and export a quality assured Plastic Recycle Cutting Blade. Highly demanded in plastic industry, it is used for cutting and threshing plastic, used for recycling purpose. Offered blade is manufactured under the proper guidance of our adroit technical experts using optimum quality materials. Besides, our clients can avail this Plastic Recycle Cutting Blade from us at feasible prices.

Features:

- Sharp edges

- Excellent strength

- Robust construction

- Made from best imported steel with suitable hardness.

- Made as per customer specification weather it is of Hard facing welding electrode , solid carbon tool steel, HCHCR steel & the inlaid tungsten carbide tip blades, essential for good cutting which reduces the machine load and enhances machine life.

- We use high quality electrodes in manufacturing of welded blades of superior quality

- Our blades are made of certified hard facing welding which maintains required hardness & quality for cutting & retains a fine cutting edge for long time.

- All products are properly heat treated to give uniform hardness & maximum cutting performance.

- Precision grinding is done to exact point of tolerance as required.

- Testing and inspection is done at all stages of production to ensure those high standards are maintained.

- We are pleased to respond favorably to your genuine enquires

Precision Cutting for Plastic Waste Recycling

These cutting blades provide precise, high-speed cutting capabilities, enabling efficient processing of rigid and thick plastic materials. The single-sided beveled edge ensures sharp and precise operation, making it ideal for recycling, granulation, and shredding applications in industrial settings.

Durable Construction for Long-Term Use

Made from high-speed or alloy steel and hardened to 58-60 HRC, these blades offer excellent wear and corrosion resistance. Their polished, uncoated surface ensures smooth operation and easy maintenance, contributing to an extended service lifespan and steady performance.

Customizable to Meet Unique Requirements

We offer customizable blade sizes and lengths, allowing you to tailor the product to your specific machinery and operational needs. Whether used in granulators, crushers, or shredders, our blades can be adapted for most plastic recycling equipment.

FAQs of Plastic Recycle Cutting Blade:

Q: How is the Plastic Recycle Cutting Blade used in plastic waste recycling?

A: The blade is installed in granulators, crushers, or shredders and is used to precisely cut, shred, or granulate plastic materials for recycling. Its design supports high-speed and heavy-duty plastic processing.Q: What materials are suitable for cutting with this blade?

A: Our blades can handle thick and rigid plastics commonly found in industrial waste streams, thanks to their heavy-duty cutting capacity and precise beveled edge.Q: When should the cutting blade be regrinded or replaced?

A: The blade should be regrinded when you notice a drop in cutting performance or increased resistance during operation. Replacement is recommended if the blades dimensions fall below safe limits after multiple regrinding cycles.Q: Where can these blades be used?

A: These blades are suitable for installation in any industrial plastic recycling machine such as granulators, crushers, or shredders, applicable in recycling facilities, manufacturing units, and plastic processing plants.Q: What is the process for customizing the blade size or shape?

A: You can specify your required length, width, or hole configuration at the time of order. Our team will manufacture the blade to match your machinerys specifications.Q: How do the blades features contribute to its benefits in operation?

A: The corrosion- and wear-resistance, in combination with long service life and regrindable edges, reduce downtime and ensure consistent, accurate cutting essential for efficient recycling operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese