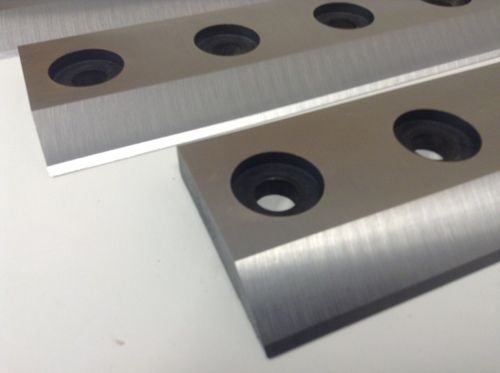

Polyfilms Cutting Blade

2000-10000 INR/Piece

Product Details:

- Material High-Speed Steel (HSS)

- Tool Type Industrial Cutter Blade

- Cutting Accuracy 0.01 mm

- Machine Type Polyfilm Cutting Machine Compatible

- Operation Type Manual/Semi-Automatic/Automatic

- Length Various Lengths Available

- Cutting Capacity Up to 300 micron thickness

- Click to View more

X

Polyfilms Cutting Blade Price And Quantity

- 20 Piece

- 2000-10000 INR/Piece

Polyfilms Cutting Blade Product Specifications

- Rectangular

- Optimized for Polyfilm Materials

- Manual or Machine Mounted

- Sharp edge, Wear resistance, Rust resistance

- Available upon request

- High

- Straight Cut

- 62-65 HRC

- Up to 300 micron thickness

- Uncoated

- Polyfilm Cutting Machine Compatible

- Manual/Semi-Automatic/Automatic

- Various Lengths Available

- 0.01 mm

- High-Speed Steel (HSS)

- Industrial Cutter Blade

- Polished

Polyfilms Cutting Blade Trade Information

- 20 Piece Per Day

- 20 Days

Product Description

Owing to our transparent business policy, we have become a trusted manufacturer and exporter of Polyfilms Cutting Blade. Offered blade is manufactured under the stern guidance of our deft professionals with the help of highly progressive techniques. The provided blade is best for cutting polyfilms. Also, this Polyfilms Cutting Blade is easily accessible in different sizes as per the requirement of our valued clients.

Features:

- Sturdy construction

- Compact design

- Excellent grip

Versatile Applications

The blades adaptability covers a broad range of uses, including polyfilm, packaging films, and plastic sheet industries. Its compatibility with various machines like slitter rewinders and bag-making units ensures operational flexibility for manufacturers and service providers.

Customizable Specifications

With customizable thickness, multiple edge types, various lengths, and the option for different blade diameters, users receive a tailor-made product fitting their specific industrial requirements. This ensures optimal performance for particular substrates and machine setups.

Durability and Precision

Featuring high wear and rust resistance, along with optimized cutting force and sharpness, these blades deliver precise, clean cuts. The ISO 9001:2015 certified manufacturing process guarantees consistent quality, making it a reliable choice for demanding production environments.

FAQs of Polyfilms Cutting Blade:

Q: How can I choose the right Polyfilms Cutting Blade thickness for my application?

A: Choose the blade thickness based on your material and cutting needs. The blade is available in 0.30 mm to 1.50 mm, making it suitable for various polyfilms and plastics. Thicker materials generally require thicker blades for enhanced stability and durability.Q: What edge type should I select: single or double beveled?

A: Single beveled edges are best for straight cuts and precise trimming, while double beveled edges suit high-speed operations and offer improved versatility for different materials. Select based on your speed and cutting accuracy requirements.Q: When should the Polyfilms Cutting Blade be replaced?

A: Blade replacement depends on the usage frequency and the thickness of materials being cut. Regular inspections for dullness or wear can help optimize blade life and maintain cutting quality. High-speed operations or cutting thicker films may need more frequent replacements.Q: Where can the Polyfilms Cutting Blade be used?

A: This blade is engineered for use in slitter rewinder machines, bag making and cutting machines, and other equipment compatible with polyfilm and packaging film processing. It integrates easily into most industrial setups and production lines.Q: What is the process of installing the blade on a machine?

A: Installation involves mounting the blade manually or by using machine settings, depending on your equipments compatibility. Ensure proper alignment and secure fastening to maximize cutting accuracy and machine safety. Follow the manufacturers guidelines for best results.Q: How does the blades quality and design benefit production operations?

A: Thanks to ISO 9001:2015 certified manufacturing, the blade ensures consistent quality, high cutting speed, and accuracy up to 0.01 mm. Its sharpness, wear resistance, and rust resistance enhance productivity and reduce downtime, making it ideal for high-volume operations.Q: What surface finish and coating does the blade offer for improved performance?

A: The blade features a polished, smooth, and burr-free surface for seamless cuts. It is uncoated but designed with high-speed steel for robust wear resistance and stability, preventing contamination in delicate film applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese