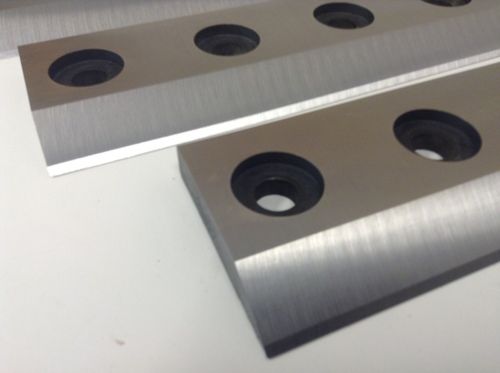

Bar Cutting Blade

2000-10000 INR/Piece

Product Details:

- Cutting Force Heavy Duty

- Material High Carbon Steel

- Cutter Type Bar Cutter Blade

- Machine Type Bar Cutting Machine

- Features Corrosion resistance, long service life, superior strength

- Hardness 58-60 HRC

- Operation Type Mechanical / Manual

- Click to View more

X

Bar Cutting Blade Price And Quantity

- 2000-10000 INR/Piece

- 20 Piece

- Yes

- 75 mm

- Construction, Rebar Cutting

- 12 mm

- Ground Finish

- Suitable for TMT and Mild Steel Bars

- Approx. 2.5 kg

- Metallic Grey

- Sharp

- 12 x 75 x 300 mm

Bar Cutting Blade Product Specifications

- 58-60 HRC

- Corrosion resistance, long service life, superior strength

- Bar Cutting Machine

- Precision

- Manual / Machine Operated

- 300 mm

- Forged

- Cutting Blade

- Uncoated

- Rectangular

- Upto 32 mm Bar

- High

- Mechanical / Manual

- High Carbon Steel

- Heavy Duty

- Bar Cutter Blade

- Yes

- 75 mm

- Construction, Rebar Cutting

- 12 mm

- Ground Finish

- Suitable for TMT and Mild Steel Bars

- Approx. 2.5 kg

- Metallic Grey

- Sharp

- 12 x 75 x 300 mm

Bar Cutting Blade Trade Information

- 20 Piece Per Day

- 20 Days

Product Description

Owing to a modernized infrastructure for trouble-free processing & post-production, we are instrumental in offering Bar Cutting Blade. Manufactured using qualitative materials and progressive technology under our experts guidance, this is used in civil construction industry for cutting iron bars. In adherence to predefined industry standards, this is also checked on certain quality parameters. Also, this Bar Cutting Blade is delivered at our clients at nominal prices.

Features:

- Robust design

- Superior strength

- Immaculate finish

Superior Material and Durability

Manufactured from high carbon steel with forged processing, the Bar Cutting Blade exhibits exceptional corrosion resistance and superior strength. This ensures long-lasting performance, even in demanding construction environments. Its hardness rating of 58-60 HRC adds to the blades durability and cutting efficiency.

Precision Cutting for Construction Needs

The blades sharp, ground finish edge delivers high cutting speed and accuracy, making it suitable for precise rebar cutting. Its rectangular shape and heavyweight design (approx. 2.5 kg) support cutting tasks for TMT and mild steel bars, providing a clean cut up to 32 mm and meeting professional standards.

Flexible Operation and Maintenance

Designed for both manual and mechanical operation, the Bar Cutting Blade integrates seamlessly with bar cutting machines. Its resharpenable feature reduces replacement costs, while the uncoated metallic surface simplifies cleaning and upkeep. This combination makes it a flexible and cost-effective solution for construction projects.

FAQs of Bar Cutting Blade:

Q: How can the Bar Cutting Blade be used for rebar in construction projects?

A: The Bar Cutting Blade is engineered for high-speed, precise cutting of TMT and mild steel rebars in construction. It is suitable for manual use as well as integration with bar cutting machines, delivering clean cuts up to 32 mm in diameter for efficient workflow on-site.Q: What process is used to manufacture this cutting blade and how does it benefit performance?

A: The blade is forged using high carbon steel, which enhances its structural integrity, increases strength, and ensures a hardness of 58-60 HRC. This manufacturing process results in superior durability and reliable cutting performance, even under heavy-duty industrial usage.Q: When should the blade be resharpened and how does this affect its lifespan?

A: Resharpening is recommended following noticeable dullness or decreased cutting speed. Regular maintenance extends the blades lifespan, reduces replacement costs, and maintains optimal cutting accuracy, making it a cost-effective choice for long-term use.Q: Where can this blade be fitted, and what types of machines is it compatible with?

A: The Bar Cutting Blade is compatible with standard bar cutting machines used in construction and steel processing. Its mechanical/manual operation versatility makes it suitable for various cutters where rectangular blades of size 12 x 75 x 300 mm are required.Q: What are the main advantages of the Bar Cutting Blades design and coating?

A: The blades sharp ground finish and uncoated metallic surface offer high cutting precision and speed, while corrosion resistance and ease of maintenance ensure long service life. Its robust rectangular shape and resharpenable feature further improve operational efficiency.Q: How does the blade ensure safety and accuracy during cutting operations?

A: With a precise ground edge and heavy-duty construction, the blade ensures stable, accurate cuts. Its design minimizes risks associated with improper cuts and reduces material wastage, supporting safe and efficient usage in busy work environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese