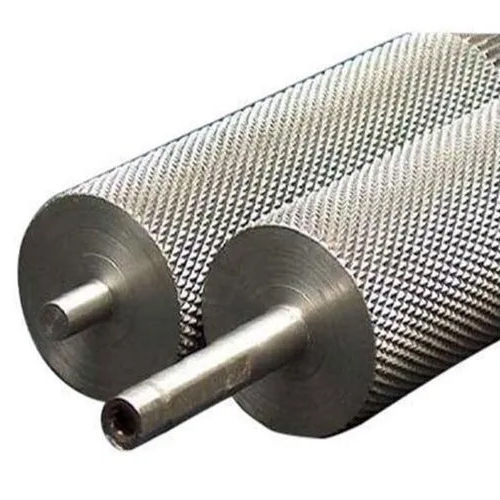

Knurling Roller

7500 INR/Piece

Product Details:

- Diameter 250 mm Millimeter (mm)

- Usage Used in Construction, Printing Machines, Rubber Industries, Etc

- Material Mild Steel

- Product Type Knurling Roller

- Color Silver

- Length 800 mm Millimeter (mm)

- Click to View more

X

Knurling Roller Price And Quantity

- 1 Piece

- 7500 INR/Piece

Knurling Roller Product Specifications

- 250 mm Millimeter (mm)

- 800 mm Millimeter (mm)

- Silver

- Used in Construction, Printing Machines, Rubber Industries, Etc

- Knurling Roller

- Mild Steel

Product Description

The Knurling Roller is a precision-engineered tool designed to create patterned impressions on metal surfaces, enhancing grip and aesthetic appeal. Commonly used in automotive, machinery, and fabrication industries, it delivers consistent, high-quality knurl patterns such as straight, diamond, and diagonal. Constructed from hardened steel, it ensures durability and resistance to wear. Ideal for manual or CNC lathe machines, the roller enables improved tactile feedback on knobs, handles, and fasteners. Featuring superior concentricity and finely ground teeth, it promotes flawless operation with minimal vibration. This tool is essential for achieving professional-grade surface finishes and functional detailing.

Precision Engineering for Multiple Industries

Designed with versatility in mind, the Knurling Roller is suitable for a range of industrial applications. Its robust mild steel construction ensures longevity and resistance to wear, making it ideal for tasks within construction, printing, and rubber processing. Whether installed in heavy-duty machinery or intricate equipment, it maintains consistent results and enhances production efficiency.

Reliable Solutions from an Indian Supplier

As an established exporter, manufacturer, service provider, and supplier in India, our Knurling Rollers meet international standards for quality and reliability. We prioritize customer satisfaction by offering prompt service and technical support, ensuring each roller seamlessly integrates with your machinery and processes, regardless of industry requirements.

FAQs of Knurling Roller:

Q: How is the knurling process performed using this roller?

A: The knurling process involves pressing the rollers patterned surface onto raw material, creating textured patterns. This enhances grip, increases bonding on surfaces, and provides essential traction for applications in printing and rubber industries.Q: What are the primary uses of the Knurling Roller with these specifications?

A: This roller is mainly used in construction machinery, printing presses, and rubber manufacturing equipment due to its substantial diameter and length, offering reliable knurling performance for large-scale operations.Q: When should I consider replacing a Knurling Roller?

A: Replacement should be considered when the roller shows signs of excessive wear, loss of pattern sharpness, or diminished efficiency in producing defined knurls. Regular maintenance inspections help determine the right time for replacement.Q: Where is this Knurling Roller manufactured and supplied from?

A: The Knurling Roller is manufactured and supplied from India, where advanced facilities ensure every product meets stringent quality standards. It is available for export and local supply to various industries.Q: What is the benefit of using a mild steel Knurling Roller?

A: Mild steel offers durability and resistance to deformation, making the roller capable of withstanding high-pressure processes. This ensures a long product life and reliable surface patterning across multiple uses.Q: How does the roller improve productivity in printing machines?

A: The rollers precise knurl pattern facilitates better adhesion and handling of printing materials, reducing slippage and improving throughput, which ultimately enhances print quality and operational speed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese