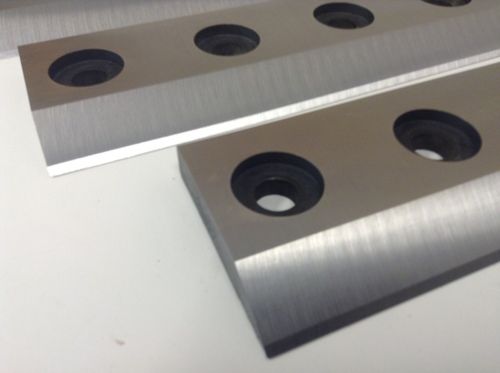

Erema Knives Blade

2000-10000 INR/Piece

Product Details:

- Operate Method Manual & Automatic

- Shape Rectangular

- Operation Type Heavy Duty

- Length Standard & Customized

- Cutting Speed High

- Cutter Type Industrial Cutter

- Cutting Force Optimized for Plastic Granulation

- Click to View more

X

Erema Knives Blade Price And Quantity

- 20 Piece

- 2000-10000 INR/Piece

Erema Knives Blade Product Specifications

- Granulator Knife / Blade

- 0.01 mm

- High Speed Steel / Tool Steel

- Up to 40 mm thickness

- Industrial Cutter

- High

- Manual & Automatic

- Standard & Customized

- Heavy Duty

- Standard for Application

- Rectangular

- Erema Plastic Recycling Granulator

- No Coating

- Excellent Wear Resistance, Sharp Edge, Corrosion Resistant

- Optimized for Plastic Granulation

- Up to 300 mm

- 60-62 HRC

- Granulation / Cutting

Erema Knives Blade Trade Information

- 20 Piece Per Day

- 20 Days

Product Description

Strongly supported by a deft team of experts, we are able to offer an unparalleled gamut of Erema Knives Blade. Under the observation of our team, this is manufactured using quality approved materials and pioneering techniques. They are all constructed to perform reliably and efficiently for trouble-free service in your successful process operation. We offer our clients a high grade of Erema Knives Blade in diverse specifications at economical price.

Features:

- Supreme strength

- Robust construction

- Light in weight

Superior Cutting Efficiency

Engineered for high-speed operation, Erema Knives Blades deliver accurate cuts with a tolerance of 0.01 mm. The optimized cutting force ensures effective granulation of plastic materials, enhancing production throughput while maintaining sharp edges and reducing wear.

Customizable for Diverse Applications

Available in standard and customized lengths, widths, and diameters up to 300 mm, these blades suit a range of industrial granulators. Whether for Erema, Nikko, or other compatible machines, users can specify dimensions for tailored solutions to meet specific plastic granulation needs.

Durability and Resistance

Constructed from premium-grade high-speed steel or tool steel, the blades offer outstanding wear resistance and corrosion protection. Their robust build, combined with precision grinding, supports heavy-duty operations, minimizing downtime and optimizing granulation processes.

FAQs of Erema Knives Blade:

Q: How are Erema Knives Blades used in plastic recycling and granules production?

A: Erema Knives Blades are mounted on granulator machines, such as those from Erema and Nikko, to cut and process plastic materials efficiently. They are essential for transforming plastic waste into granules, streamlining the recycling process.Q: What benefits do single and double bevel edge types offer?

A: Single bevel edges provide precise cuts, ideal for uniform plastic granulation, while double bevel edges enhance cutting versatility and reduce resistance, improving blade efficiency and extending operational life.Q: When should I opt for customized blade sizes or shapes?

A: Customized blades are recommended when specific machine configurations, material types, or processing requirements demand unique dimensions. Customization ensures maximum compatibility and optimal cutting performance.Q: Where are these blades manufactured and supplied?

A: Erema Knives Blades are manufactured, exported, and supplied by experienced providers in India, serving global plastic recycling and granulation industries.Q: What is the process for ordering and receiving Erema Knives Blades?

A: Orders can be placed with a minimum quantity of 10 pieces. Sizes, shapes, and specifications are tailored upon request, and blades are safely packed in boxes or cartons for secure delivery.Q: How does the precision ground surface finish benefit my operations?

A: The precision ground finish ensures sharpness, consistent cutting accuracy, and reduced friction during operation. This results in lower wear, better granulation quality, and prolonged blade life.Q: What usage recommendations enhance blade effectiveness?

A: To maximize effectiveness, select the correct material and edge type for your application, perform regular maintenance, and choose the appropriate size and shape compatible with your granulator machine.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese