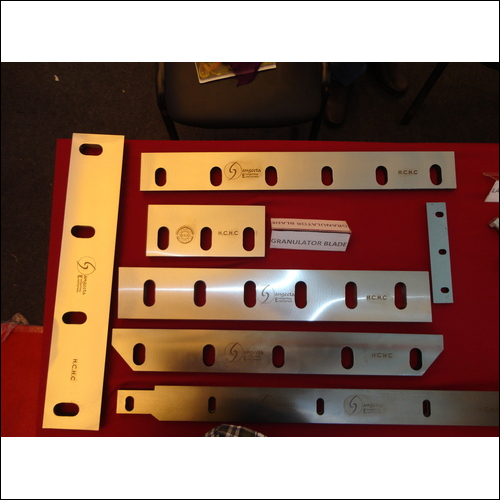

Pet Strap Cutting Blades

2000-10000 INR/Piece

Product Details:

- Machine Type Strapping Cutting Machine

- Cutting Accuracy 0.05 mm

- Operation Type Manual/Automatic

- Cutting Speed High Speed

- Cutting Capacity Suitable for PET Strap 9mm to 25mm

- Hardness HRC 58-60

- Coating Type Anti-rust

- Click to View more

X

Pet Strap Cutting Blades Price And Quantity

- 20 Piece

- 2000-10000 INR/Piece

- Single and Double Edge Variants

- Set of 10 Blades

- Polished

- Up to 150,000 Cuts

- Designed for cutting PET Straps in Packing Industries

- PET, PP, Polyester Straps

- Length: 100 mm, Width: 25 mm, Thickness: 5 mm

- ±0.02 mm

- Approx. 150 grams per blade

- Silver

Pet Strap Cutting Blades Product Specifications

- Rectangular

- Manual and Machine Operated

- High Wear Resistance, Long Life, Easy Replaceability

- Alloy Tool Steel

- 100 mm

- Cutting Blade

- Anti-rust

- Optimized for Manual and Automatic Cutting

- PET Strap Cutter

- Corrosion Resistant

- High Speed

- Precision Forged

- Suitable for PET Strap 9mm to 25mm

- HRC 58-60

- 0.05 mm

- Manual/Automatic

- Strapping Cutting Machine

- Single and Double Edge Variants

- Set of 10 Blades

- Polished

- Up to 150,000 Cuts

- Designed for cutting PET Straps in Packing Industries

- PET, PP, Polyester Straps

- Length: 100 mm, Width: 25 mm, Thickness: 5 mm

- ±0.02 mm

- Approx. 150 grams per blade

- Silver

Pet Strap Cutting Blades Trade Information

- 20 Piece Per Day

- 20 Days

Product Description

With our rich industrial experience and expertise, we have become a prominent manufacturer and supplier of Pet Strap Cutting Blades. The offered blades are manufactured using excellent quality materials with the aid of cutting-edge techniques. Easily installed in industrial machines for smooth functioning, we made the provided blades available in different sizes as per clients' demands. In addition, these Pet Strap Cutting Blades can be purchased from us at marginal prices.

Features:

- Light weight

- Easy to fit

- Robust built

High-Performance Blade Design

Manufactured using precision forging and crafted from robust alloy tool steel, the Pet Strap Cutting Blades come in single and double edge variants to suit diverse cutting requirements. Their corrosion-resistant coating and polished finish extend operational life and maintain peak performance under heavy usage.

Wide Application Range

Engineered for compatibility with PET, PP, and polyester straps, these blades can be used in both manual and automatic strapping machines. Recommended for cutting straps ranging from 9 mm to 25 mm in width, their optimized cutting force and high wear resistance make them suitable for packaging operations of various scales.

Long Service Life and Easy Replacement

Each blade delivers up to 150,000 efficient cuts, minimizing downtime and maximizing productivity. Their standardized dimensions and anti-rust coating facilitate quick and easy replacement, ensuring seamless transitions and consistent performance in packing environments.

FAQs of Pet Strap Cutting Blades:

Q: How do I correctly use Pet Strap Cutting Blades with packing machines?

A: To use Pet Strap Cutting Blades, install them in compatible manual or automatic strapping cutting machines. Ensure the blades are properly secured and align your PET, PP, or polyester straps (ranging from 9 mm to 25 mm width) into the designated cutting slot for safe and precise operation.Q: What types of materials can these cutting blades process effectively?

A: These blades are specifically designed for cutting PET straps but are also recommended for PP and polyester straps, making them versatile for various packing applications in industries that require efficient strap cutting.Q: When is it necessary to replace the blades in strapping machines?

A: Blades should be replaced after reaching their service life, which is up to 150,000 cuts, or if you notice a decrease in cutting efficiency, accuracy, or visible wear and tear. Easy replaceability ensures minimal interruption during replacement.Q: Where can these blades be applied within the packing industry?

A: Pet Strap Cutting Blades are suitable for use in packing lines requiring manual or machine-operated strap cutting. They are ideal for exporters, manufacturers, service providers, and suppliers involved in securing palletized goods and bundles with PET, PP, or polyester straps.Q: What is the process for maintaining the blades and prolonging their life?

A: Maintaining the blades involves regular cleaning to remove residue, ensuring the anti-rust coating remains intact, and inspecting for signs of wear or corrosion. Store blades in dry conditions and use only within recommended materials and machine settings to maximize their service life.Q: What benefits do these blades offer for high-volume packing operations?

A: The blades deliver high-speed cutting with superior accuracy (0.05 mm), robust wear resistance, and long service life. Their ease of replacement and corrosion-resistant coating help keep packing lines running efficiently with minimal maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese