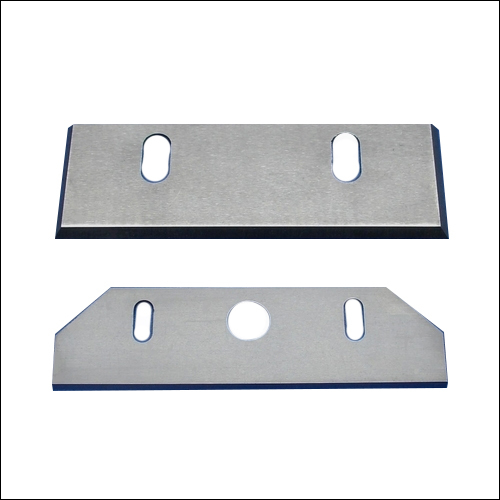

Fibre Cutting Blade

2000-10000 INR/Piece

Product Details:

- Operation Type Continuous/Intermittent

- BladeSize Custom/Standard Sizes Available

- Length Varies by Blade Size

- Cutting Accuracy Precision Cutting

- Coating Type None/Plain

- Hardness High (suitable for cutting synthetic fibre)

- Cutter Type Fibre Cutting Blade

- Click to View more

X

Fibre Cutting Blade Price And Quantity

- 20 Piece

- 2000-10000 INR/Piece

- Lightweight

- Mirror Finish or Matte

- Silver/Grey Metallic

- Regrindable

- Fits Most Standard Fibre Cutting Machines

- High

- Long Lasting Under Regular Use

- Up to 350°C

- Box or Custom Pack

Fibre Cutting Blade Product Specifications

- Fibre Cutting Machine Compatible

- High Speed Compatible

- Optimized for Fibre Materials

- Rust Resistance, Extra Sharp, Precision Ground

- Low Required with Efficient Sharpness

- Designed for Industrial Usage

- 90 mm

- Round

- Uncoated

- Circular Cutting Blade

- None/Plain

- Fibre Cutting Blade

- High (suitable for cutting synthetic fibre)

- Cutting

- Continuous/Intermittent

- Varies by Blade Size

- Precision Cutting

- Custom/Standard Sizes Available

- Lightweight

- Mirror Finish or Matte

- Silver/Grey Metallic

- Regrindable

- Fits Most Standard Fibre Cutting Machines

- High

- Long Lasting Under Regular Use

- Up to 350°C

- Box or Custom Pack

Fibre Cutting Blade Trade Information

- 20 Piece Per Day

- 20 Days

- All India

Product Description

Fibre Cutting Blade

We make available an exclusive range of Fibre Cutting Blade, which is appreciated by our valuable clients for their high tensile strength, durability, rugged design and dimensional accuracy. Developed by our experts using imported steel, these blades efficiently serves the fiber cutting requirements in the industry. Available in various specification, our Fibre Cutting Blade can be customized as per the exact demands of our clients.

More Details:

- Plastic industries Blades

- We offer an extensive range of advance plastic processing blades for a wide variety of applications.

- We are manufacturing all kind of industrial blades used in plastic reprocessing industries.

Our regular types of blades are

- Agglomerator blade

- Granulator blade

- Mixer blade

- Pelletizers blade

- We also provide any kind of blades as per customer requirements.

Our knives blades are

- Made from best imported steel with suitable hardness.

- Made as per customer specification weather it is of Hard facing welding electrode , solid carbon tool steel, HCHCR steel & the inlaid tungsten carbide tip blades, essential for good cutting which reduces the machine load and enhances machine life.

- We use high quality electrodes in manufacturing of welded blades of superior quality

- Our blades are made of certified hardfacing welding which maintains required hardness & quality for cutting & retains a fine cutting edge for long time.

- All products are properly heat treated to give uniform hardness & maximum cutting performance.

- Precision grinding is done to exact point of tolerance as required.

- Testing and inspection is done at all stages of production to ensure that high standard is maintained.

- We are pleased to respond favorably to your genuine enquires

Features

- Large range of granulator and palletiseing blades suitable for granulating, palletizing and dicing of plastic or manmade fibres.

- Correct balance of shock and wear resistance and excellent durability to ensure smooth operation which increases the cutting efficiency for all grades of polymers and elostomers

- Optimum hardness and toughness.

Superior Surface Finish and Material Quality

Choose between a mirror or matte surface finish to match your operational needs. The blade features a premium silver/grey metallic appearance, crafted from materials engineered for excellent hardness and cutting performance, ensuring long-lasting sharpness and resistance against rust and corrosion.

Designed for High Compatibility and Versatility

Our cutting blades fit most standard fibre cutting machines, offering seamless integration for various industrial applications. Lightweight construction allows for easier handling, while custom and standard sizes extend usability across a wide range of fibre materials and machine setups.

Engineered for Industrial Performance and Precision

With high temperature resistance (up to 350C), precision-ground edges, and low required cutting force, this blade is optimized for maximum productivity. Its high-speed compatibility enhances throughput, while the regrindable edge maximizes blade lifespan and cost-efficiency for ongoing operations.

FAQs of Fibre Cutting Blade:

Q: How do I determine if this fibre cutting blade fits my cutting machine?

A: Our fibre cutting blades are engineered to be compatible with most standard fibre cutting machines. Please check your machines specifications for diameter and mounting types to ensure proper fit, or contact us with your machine details for guidance.Q: What is the recommended process for sharpening or regrinding the blade?

A: The blade is regrindable and should be sharpened using a suitable grinding mechanism designed for circular cutting blades. We suggest consulting a professional tool sharpening service or following your machine manufacturers guidelines for best results.Q: Where is this fibre cutting blade best utilized?

A: This blade excels in industrial settings where synthetic fibre material needs efficient, precise cutting. Its ideal for textile, technical fabric, and composite fibre industries, suitable for both small-scale workshops and large manufacturing plants across India and globally.Q: What benefits do the mirror finish and high hardness provide?

A: A mirror finish minimizes residue build-up and friction during cutting, enhancing cutting accuracy and cleanliness. The blades high hardness allows it to retain sharpness for extended periods, making it suitable for high-speed and precision applications in synthetic fibre processing.Q: When should I consider replacing the cutting blade?

A: Replace the blade when noticeable dullness occurs, when precision falls off, or if chips/cracks become visible. However, because the blade is regrindable and long-lasting under regular use, proper maintenance extends its usable life considerably.Q: How does the blades temperature and corrosion resistance contribute to performance?

A: With resistance to temperatures up to 350C and high protection against corrosion, the blade performs reliably in harsh operating environments. These features ensure consistent precision and longevity, even during continuous industrial use.Q: What type of packaging is available for the fibre cutting blade?

A: Blades are typically supplied in robust box packaging for safety during transport, though custom packaging can be arranged according to specific requirements. This ensures the blades surface and cutting edge remain protected until ready for use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese