Plastic Granulator Machine

300000.00 INR/Volt

Product Details:

- Accuracy High

- Cooling System Water Cooling

- Plastic Processed PET, PP, PE, PVC

- Voltage 380 V

- Machine Type Granulator

- Lubricating System Automatic Lubrication

- Motor Power 22 kW

- Click to View more

X

Plastic Granulator Machine Price And Quantity

- 1 Volt

- 300000.00 INR/Volt

- 200000.00 - 500000.00 INR/Volt

Plastic Granulator Machine Product Specifications

- Ambient

- Automatic Lubrication

- Mechanical Cutting

- 22 kW

- Electric

- 1800 mm x 1200 mm x 1500 mm

- PET, PP, PE, PVC

- Water Cooling

- High

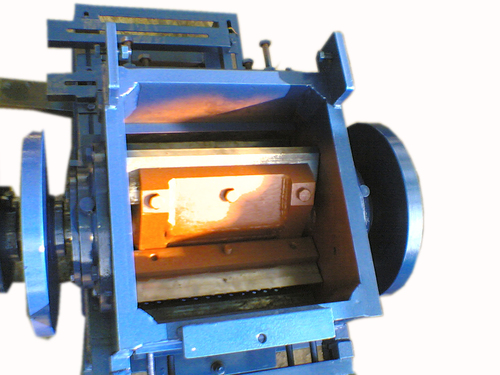

- Blue & White

- Granulator

- 380 V

- Automatic

- Plastic Granulator Machine

- Powder Coated

- <75 dB

- Standard Electrical Connectors

- 22 kW

- Plastic Recycling, Granulating Waste Plastics

- Rigid Steel Frame

- 50 Hz

- 22 kW

- 1200 kg

- PLC Control

- Direct Drive

Plastic Granulator Machine Trade Information

- 20 Volt Per Day

- 20 Days

- According to products

- All India

Product Description

Plastic Granules Machine

We are a quality centric organization, presently entertaining our clients with exceptional range of Plastic Granules Machine. The blades integrated with these machines are developed with the use of high grade alloy steel and other material, thus provide excellent performance during crushing of plastic granules. Our Plastic Granules Machine is acknowledged by world wide spread clients for their attributes like sturdy construction, easy maintenance, less power consumption and long service life.

Further Details

- The profile of rotter is so designed that the feed material will not jammed into a rotter while running.

- Rotter is dynamically balanced to minimize the vibration, which result in longer life to a bearing.

- Our granulators are fitted with best quality cutting blades & are designed to consume low power.

Features

- Easy to operate & easy to clean.

- Hopper designed & fabricated for your special requirements.

- Rotary & stationary blades made of high carbon / high chrome tooled steel & especially heat treated for longer life.

- Open rotter design provides maximum cooling, increases operator's efficiency & decreases noise level.

- Rotter is fitted with 3 rotary blades & located on roller bearings at both the end.

- Rotary are set at an angle & can like the stator blade , be sharpened several times & cuts the material with a "scissor action" to minimize the power consumption &amount of dust

- Economical efficiency and quality of product are synonymous with the company policy is to satisfy client requirement

Efficient Granulation and High Throughput

This granulator features six rotating and four fixed high carbon alloy steel blades powered by a 22 kW electric motor. The combination of a wide 500 mm feeding port and efficient mechanical cutting allows fast processing of various plastic types, significantly increasing material throughput for recycling plants.

Durable Build and Enhanced Safety

Constructed from stainless steel and mild steel with a powder-coated finish, the machine is built to last in industrial settings. Important safety mechanisms include an emergency stop button and overload protection, ensuring secure operation and minimal downtime during use.

Comprehensive Maintenance and Service Support

With an easy-to-follow maintenance schedule of every six months, plus automatic lubrication and water cooling systems, routine care is simplified. Rapid onsite and remote support ensures operational continuity, making this machine a reliable choice for continuous plastic recycling applications.

FAQs of Plastic Granulator Machine:

Q: How does the high carbon alloy steel blade material benefit the granulation process?

A: High carbon alloy steel blades offer superior hardness and wear resistance, ensuring consistent cutting performance and a longer operational lifespan, reducing the need for frequent blade replacements during plastic granulation.Q: What types of plastic can this granulator machine efficiently process?

A: The machine efficiently granulates a variety of thermoplastics such as PET, PP, PE, and PVC, making it versatile for a wide range of plastic recycling and waste management applications.Q: When is routine maintenance required for optimal performance?

A: Routine maintenance should be performed every six months. The machines automatic lubrication and water cooling systems further support hassle-free maintenance and prolong key component life.Q: Where is service support for this granulator machine available?

A: We provide both onsite and remote technical support for this plastic granulator across India, ensuring customers receive timely professional assistance wherever their facility is located.Q: What safety features are equipped in this granulator for operator protection?

A: Operator safety is a priority, featuring an emergency stop button and overload protection system. These mechanisms reduce the risk of accidents and equipment damage during operation.Q: How does the PLC control system improve machine operation?

A: The integrated PLC control system allows precise and automated operation, enhancing process accuracy, repeatability, and user convenience. This contributes to optimal granule size and consistent product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Crusher Machine' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese